OUR COMMITMENT TO EXCELLENCE

MÉDITERRANÉE POLYESTER (MÉDIT-POL) Roadmap to Triple ISO Certification – Starting Q1 2026 9001 (Quality) • 14001 (Environment) • 45001 (Health & Safety)

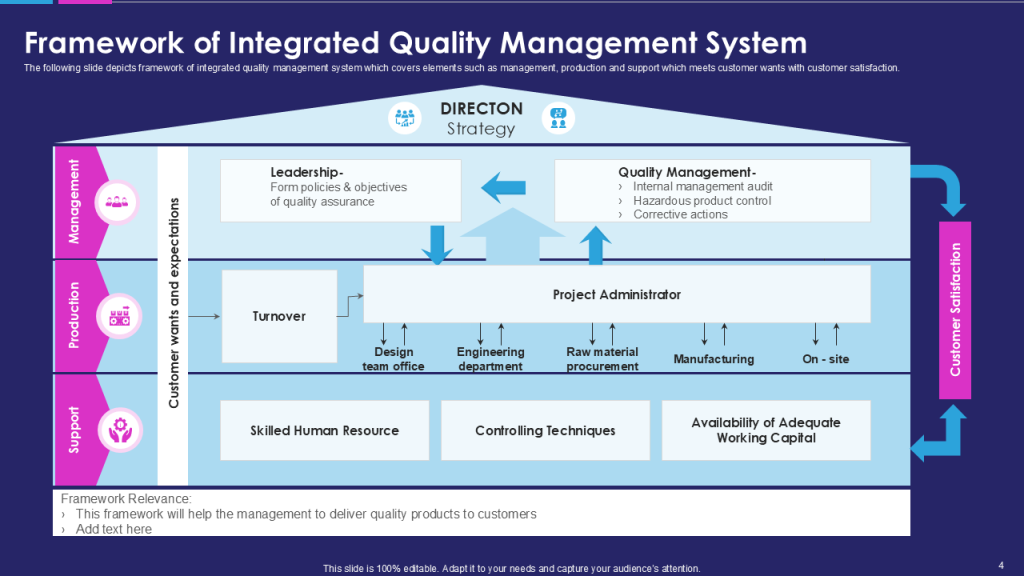

Founded in 1998 as a family SARL specializing in fiberglass-reinforced polyester composites for marine, vehicles, pools & cabins – we are launching an Integrated Management System (IMS) project to achieve certification by end of 2027. This positions Médit-Pol as Algeria’s leading responsible composite manufacturer: consistent quality, eco-friendly resin/waste management, safe workshops.

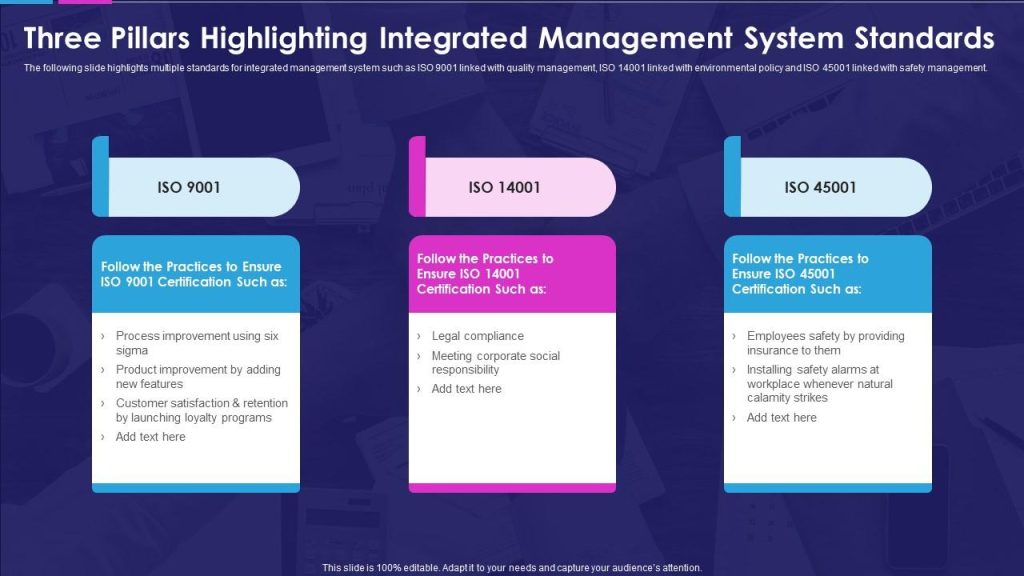

Standards Resume – Why Triple Certification?

| Standard | Short Resume | Key Benefits for Médit-Pol Composites |

|---|---|---|

| ISO 9001:2015 | Global Quality Management System (QMS) standard for consistent processes, customer focus & continual improvement via PDCA cycle. | Uniform high-quality parts (boat hulls, vehicle panels); reduced defects/waste in lay-up; higher partner satisfaction; market access (exports). |

ISO 14001:2015  ISO 14001 Environmental Management System. ISO 14001 Environmental Management System. | Environmental Management System (EMS) for identifying impacts, compliance & efficiency (waste, energy, emissions). | Optimized resin/fiberglass use; reduced hazardous waste (styrene, scraps); energy savings in molding; regulatory compliance; green reputation. |

| ISO 45001:2018 | Occupational Health & Safety (OH&S) system to proactively manage workplace risks & promote worker well-being. | Safer handling of resins/fibers (PPE, ventilation); fewer accidents in workshops; lower insurance/absenteeism; motivated team of 30+. |

Our 3-Phase Roadmap (Total: ~24 Months – Realistic for SME Manufacturer)

🗺️ Phase 1 – Preparation & System Building Q1 2026 – Q1 2027 (~12 months) | Foundations for IMS

- Gap analysis vs. 3 standards (current processes audited)

- Integrated policy/objectives (Quality-Env-Safety) & risk assessments (resins, fiberglass dust, waste)

- Document IMS: procedures, forms, KPIs (e.g., defect rate <2%, waste -20%, zero lost-time incidents)

- Train 30+ staff (management first)

IMS Manual (ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018 …

🚀 Phase 2 – Implementation & Integration Q2–Q3 2027 (~6-9 months) | Daily Excellence

- Deploy across production/logistics: lay-up controls, waste sorting, safety protocols (PPE, chem handling)

- Full staff training/awareness; supplier audits

- Internal audits & management reviews; fix nonconformities (e.g., improve ventilation for fiberglass)

- Monitor KPIs: quality yields, waste tons, safety incidents

✅ Phase 3 – Validation & Certification Q4 2027 (~3-6 months) | Official Recognition

- Final internal audit cycle

- Stage 1: Documentation review

- Stage 2: On-site audit (production witness, interviews)

- Triple certificates issued! + Annual surveillance Target: Certified by Dec 2027 (18-24 months typical for integrated SME per ISO timelines)

Process Approach – PRETESH BISWAS

Join our journey to certified leadership in Algerian composites! Benefits: Lighter vehicles, durable boats, zero-compromise safety – trusted by partners.

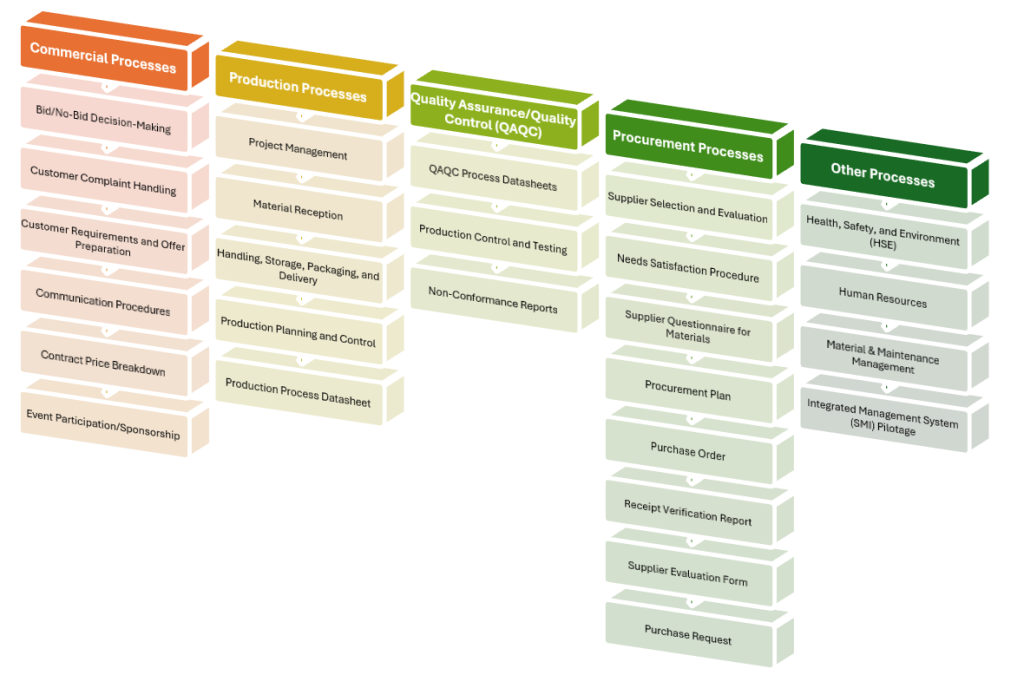

DOCUMENTS OVERVIEW